The fun part of making your own lures is you can make them exactly the way you want, which is what I have started doing, and will try to explain in this post

I have edited this post over the last few days to show how I do it

To those that have helped me improve the way I do it, thank you.

I bought some raw jigs (not doing the whole lead buying and mould thing, atleast not at this stage)

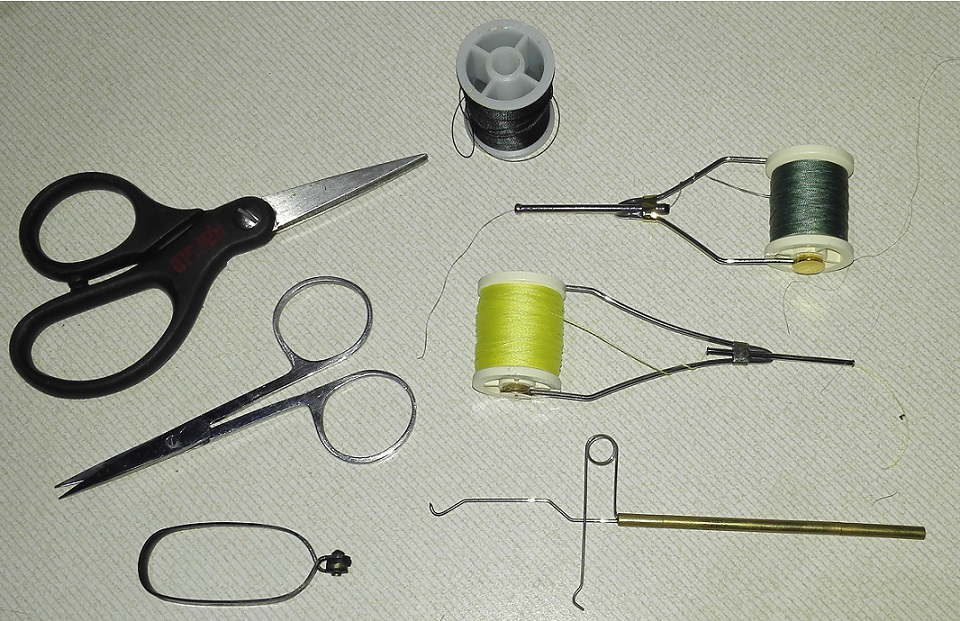

There are some specific tools that you need to make the journey easier, but in most cases I improvise with what I have.

The intention is to have a hobby and to make my own bucktail jigs, not to go bankrupt.

Watch this space it's gonna be fun

Update Notes

Just a note, there are many videos on youtube that show you the whole process ...

I have edited this post over the last few days to show how I do it

To those that have helped me improve the way I do it, thank you.

I bought some raw jigs (not doing the whole lead buying and mould thing, atleast not at this stage)

There are some specific tools that you need to make the journey easier, but in most cases I improvise with what I have.

The intention is to have a hobby and to make my own bucktail jigs, not to go bankrupt.

Watch this space it's gonna be fun

Update Notes

- 5 August 2017

- 9 August 2017

Just a note, there are many videos on youtube that show you the whole process ...