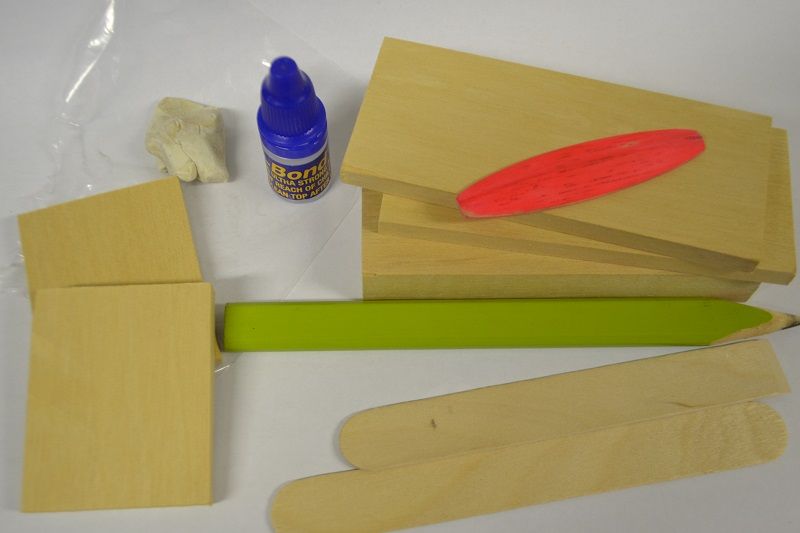

In order to allow myself the option of modifying the spoon later by making it a little heavier or lighter by increasing the thickness and also to allow myself the option in increase the sprew size, I decided that I will make the one mould half recess into the other. You will see later what I mean.

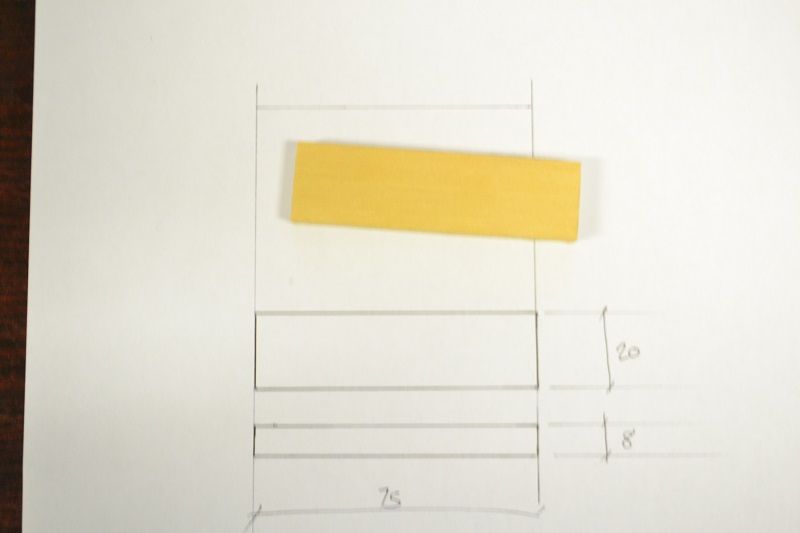

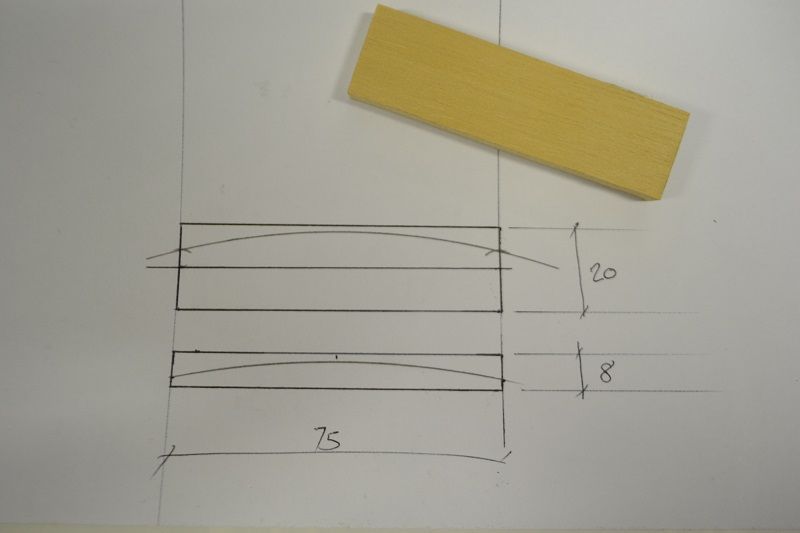

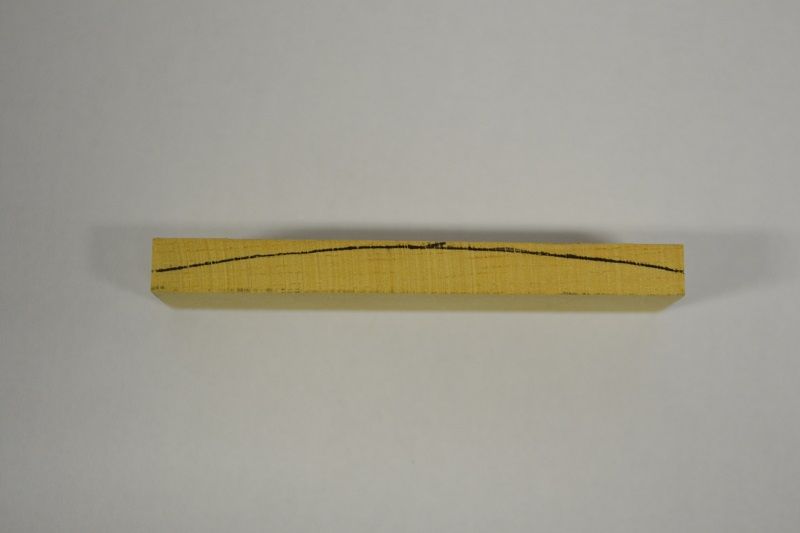

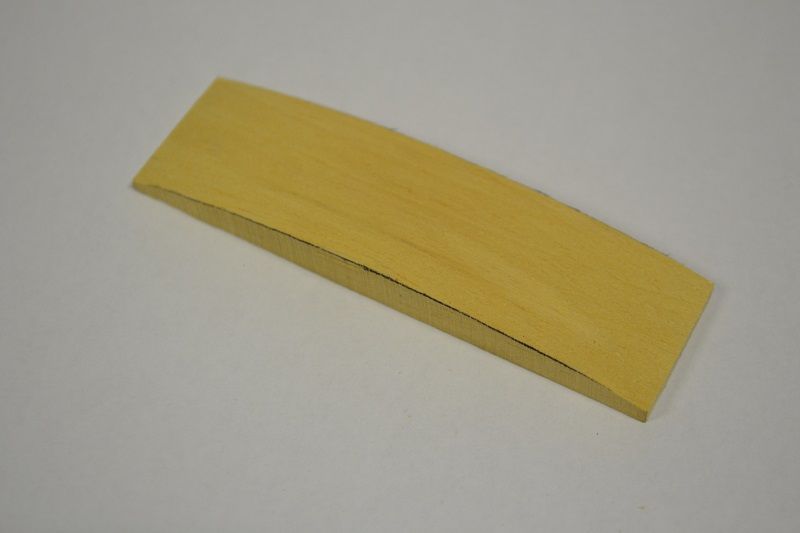

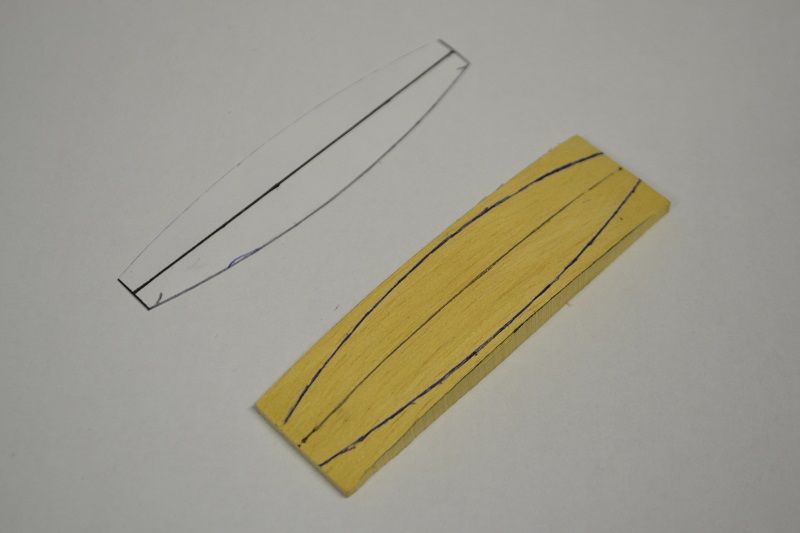

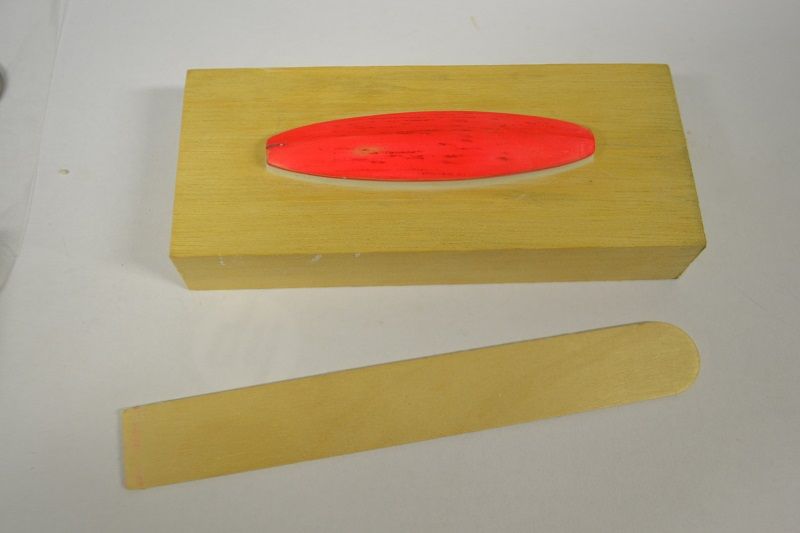

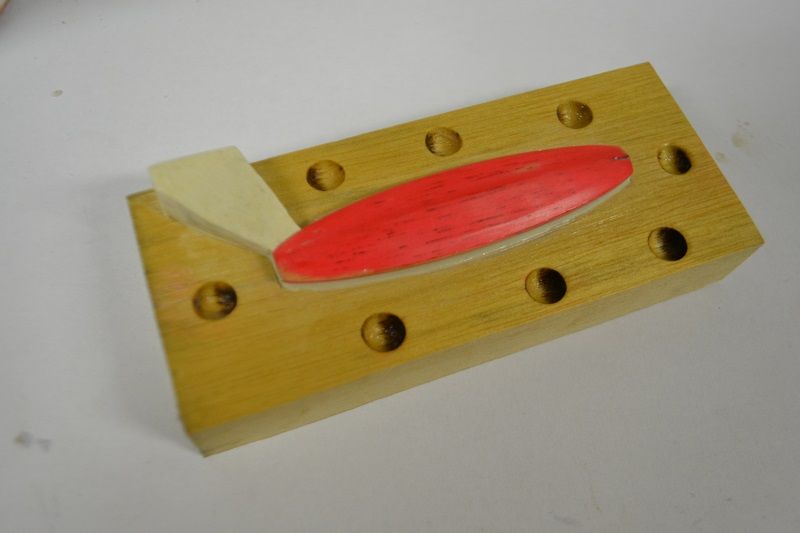

On the 20mm thick piece of wood, I marked where the lure should be positioned in the mould. You need minimum 10mm material around the spoon, I would recommend at least 15mm. I could have put it at a bit of an angle to facilitate the the pouring but to save materials I'll rather make it level and lean the mould slightly when pouring.

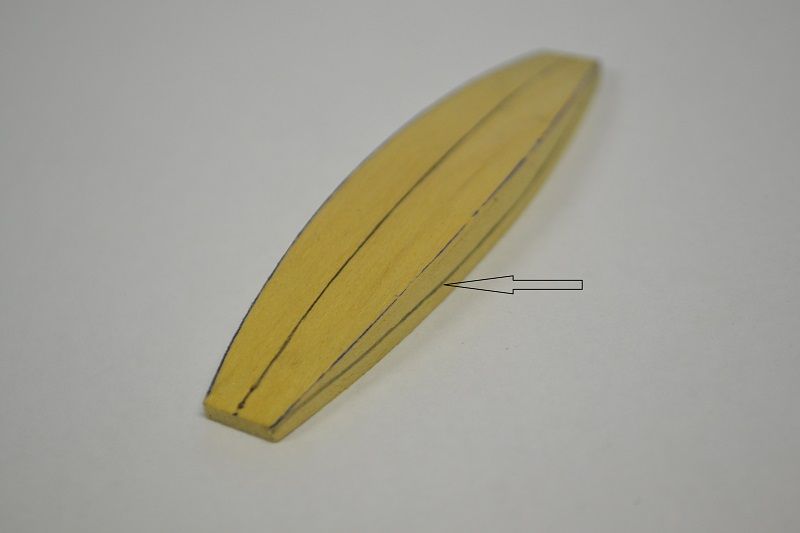

After marking the position, I cut a small piec of the tong depressor and glued it in the center just to lift it approximately 2mm.

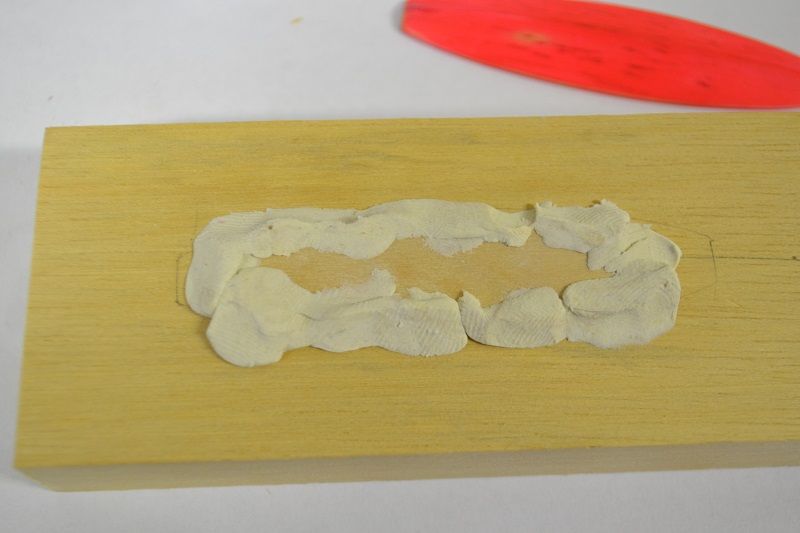

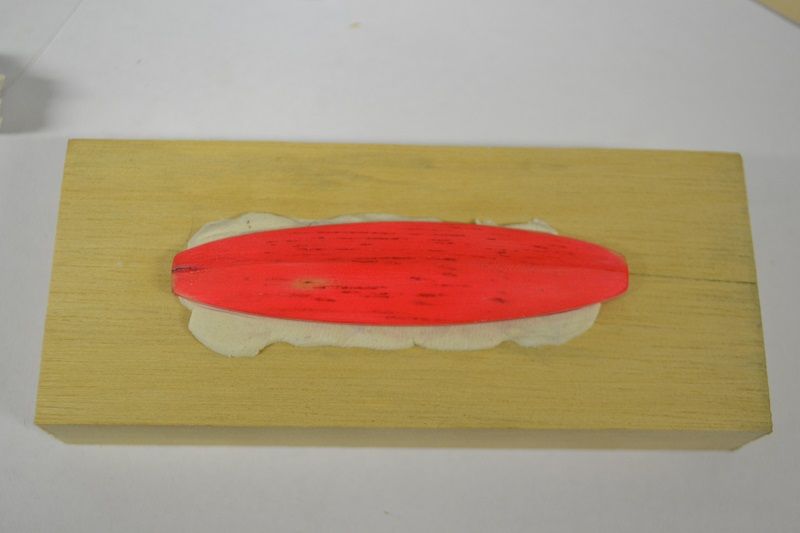

Then place some putty around the edges to hold the plug in position. Lay down extra that can be scraped clean later.

Stick the plug down.

Scape the edges straight and clean with the squared off depressor.

Before continuing place it in the freezer for 15min. This will harden the clay considerably and help keep everything put.

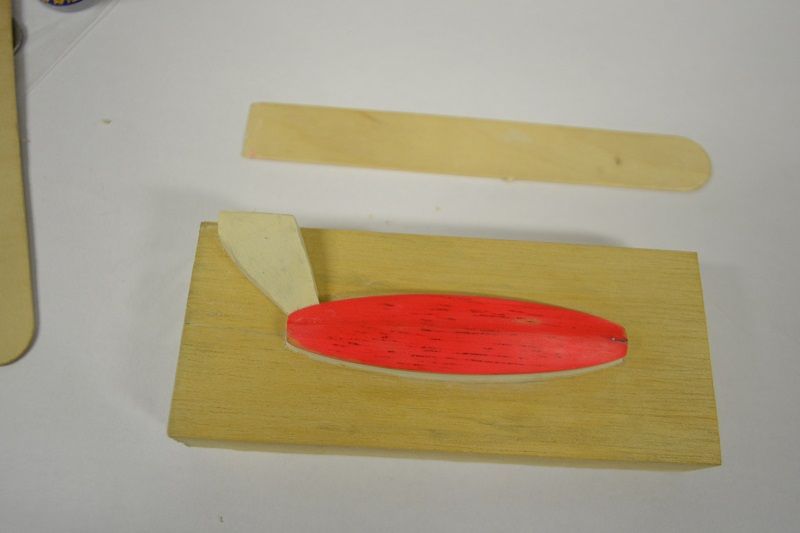

Now develop the sprew.

Place in freezer for another 15min to make the prew hard.

Next we need keys. For this you can use anything really. The half rounds you buy to stick over screws work nice. Or, as I did here, I used a round dremel tool to make half round indentations. I have used a counter sinking bit als on the past.

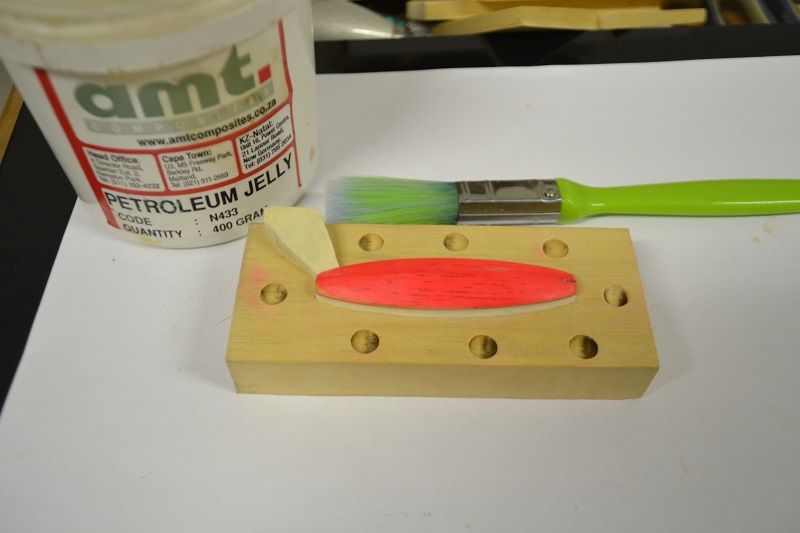

Next, coat the entire piece of wood with a very light coating petroleum jelly (Vaseline). IT IS NOT NECESSARY TO COAT THE PLUG or prew. To be honest, you dont even really need to coat the wood. The only thing you need a barrier against is silicone. Silicone sticks to nothing but silicone. You don't even need to coat the wood with any barrier to be honest but it just helps to smooth out the wood grain. The silicone will seep into every tiny little groove.

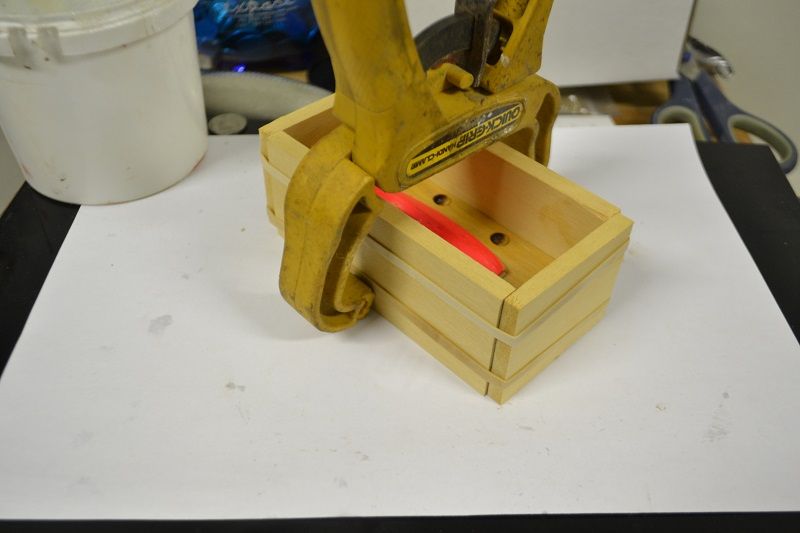

Next we place the 115X50X5 pieces of wood on the long edges and hold it in place with a clamp.

Then the 2 shorter planks and hold them in place with elastic bands.

Now you need to smear every joint with petroleum jelly to prevent leakage.

Your mould box is now ready. Next we look at the silicone, mixing and pouring.